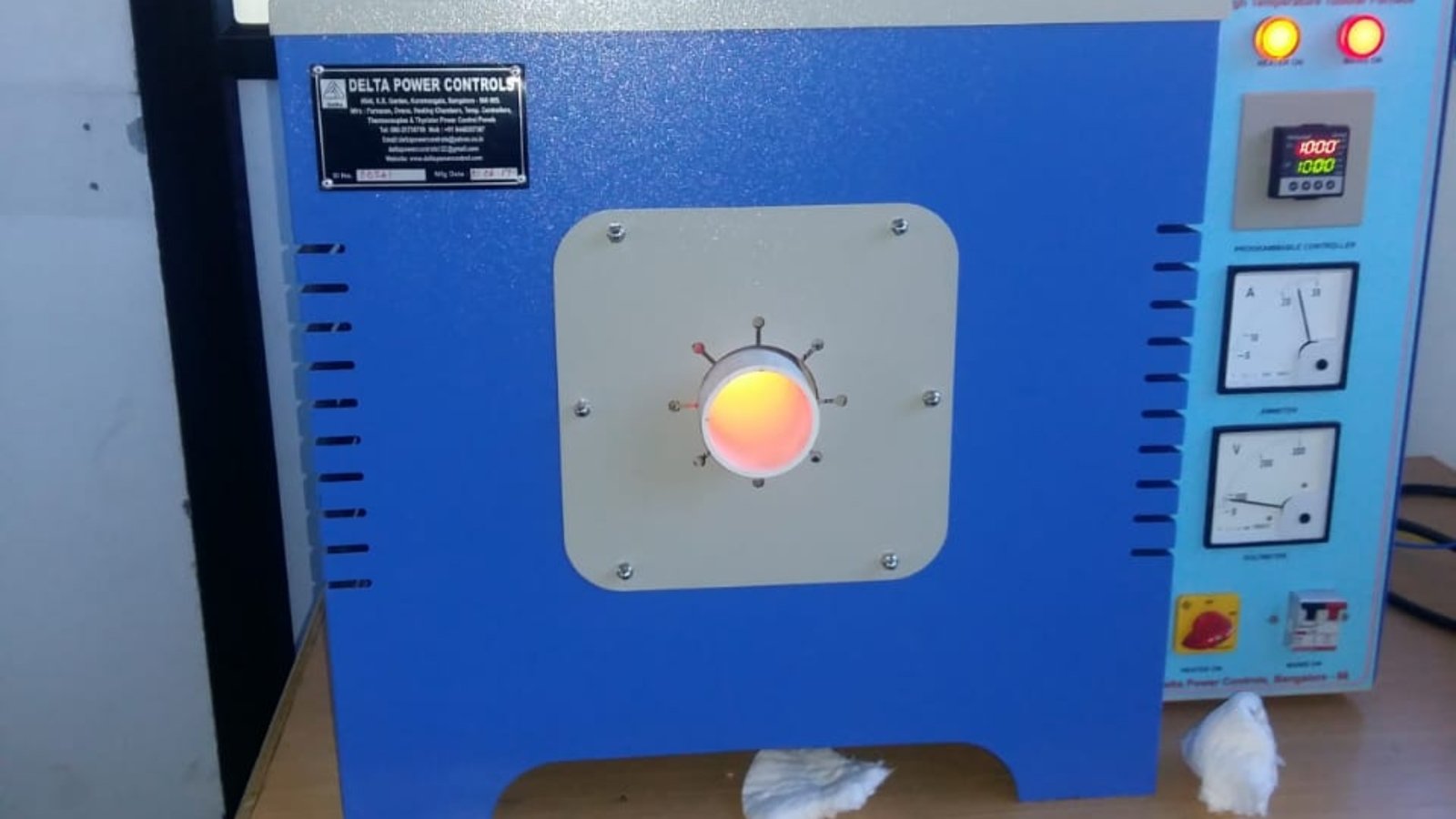

High Temperature Tubular Furnace – 1400 deg C

A high-temperature tubular furnace capable of reaching 1400 degrees Celsius is a type of furnace commonly used in industrial and scientific applications that require high-temperature heating. The furnace typically consists of a cylindrical tube made from high-temperature resistant materials such as ceramic or quartz, which is heated using a heating element located outside the tube.

The furnace can be used for a variety of applications, such as annealing, sintering, and heat treating of materials. It is often used in materials science research, semiconductor manufacturing, and metallurgy.

To operate the furnace, the sample to be heated is placed inside the tube, and the temperature is set using a temperature controller. The furnace is then heated to the desired temperature, and the sample is held at that temperature for a specified amount of time. The temperature can be ramped up or down at a controlled rate, depending on the specific heating requirements.

It is important to note that safety precautions must be taken when operating a high-temperature furnace, as temperatures above 1000 degrees Celsius can be hazardous. Protective equipment such as gloves, safety glasses, and heat-resistant clothing should be worn, and the furnace should be operated in a well-ventilated area. Additionally, proper training and experience are required to safely operate a high-temperature furnace.